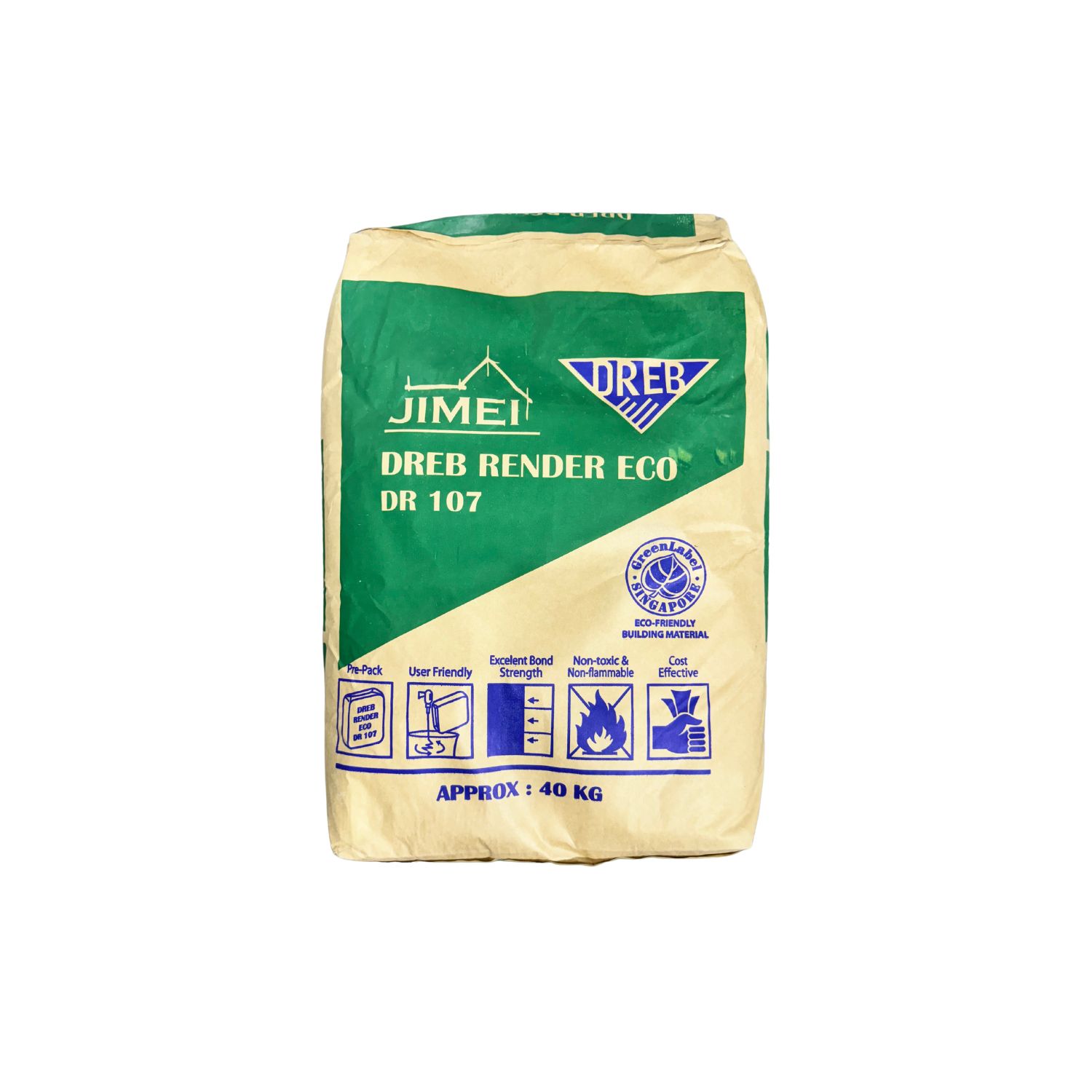

DREB Skim Coat (White) – External

DREB Skim Coat (White) – External

DREB Skim Coat ECO (EXTERNAL) is special formulated for high quality, it is good to finish on all types of concrete surfaces such as column, beam, stab, lightweight block wall and to finish plaster surfaces. It contents additive that improve workability, consistency, water retentively and bond strength. Should not apply on all painted surfaces.

Surface preparation

All surface must be structurally sound, clean, and free from dust, or others foreign materials that effect adhesion and bonding. For dry or high absorbing substrates, pour the surfaces with water prior.

Mixing

Add 40 kg of DREB Skim Coat ECO (EXTERNAL) with 12 to 13 litres of water. Mix thoroughly with an electrical mixer or manually for about 3 to 5 minutes until the desired homogeneous paste is obtained.

Application

Apply with using a steel trowel to a maximum thickness of 3mm and cured under shaded ambient conditions. After about 4 hours, the second coat is applied such that total thickness does not exceed 6mm. It will remain workable for approximately 60

minutes after mixing.

DREB Skim Coat ECO (External) can be finished with soft hair brush or trowelled smooth. It is important to protect the product during placement and whilst curing from direct sunlight

and winds.