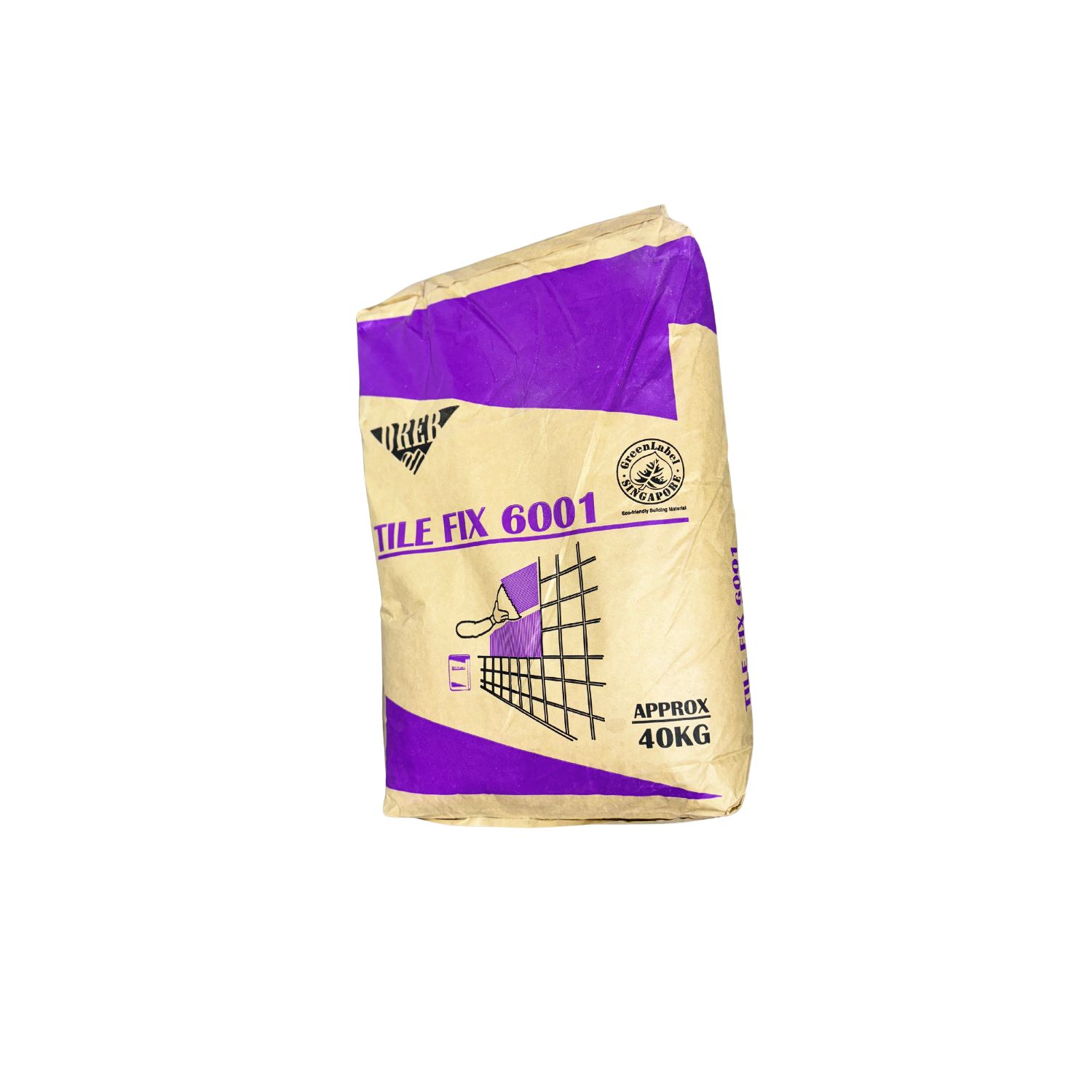

Surface preparation

All surface of substrates should be clean and remove from oil, grease, dust and others contaminants. Dry substrates should be dampened before application. For old worn out concrete substrates, the surface should be hacked off and buttering with bonding agent before applying them.

Mixing

Mixing should use the clean water and mix thoroughly using a hand-held or mechanical mixer for 3-7 minutes until a desire homogenous mix is achieved and ensure the mix is free from lumps. The mix ratio is add approximately 5.0 - 6.0 litres of clean water to 40 kg bag.

Coverage

Coverage varies according to surface condition and the build-up required. The following can be used as an approximate guide: - Using a 4.5mm x 4.5mm notched trowel, approximately 2 kg/m2 - Using a 6mm x 6mm notched trowel, approximately 2.5 kg/m2 - Using a 10mm x 10mm notched trowel, approximately 3.5 kg/m2

Application method

Apply them by use a steel trowel, wooden/steel float while the mix is still workable for application onto the substrate and concrete. It should be cured for at least 1 day (24 hours) before any tiling works.